LATEST NEWS

Where does training fit in a quality culture❓❓❓

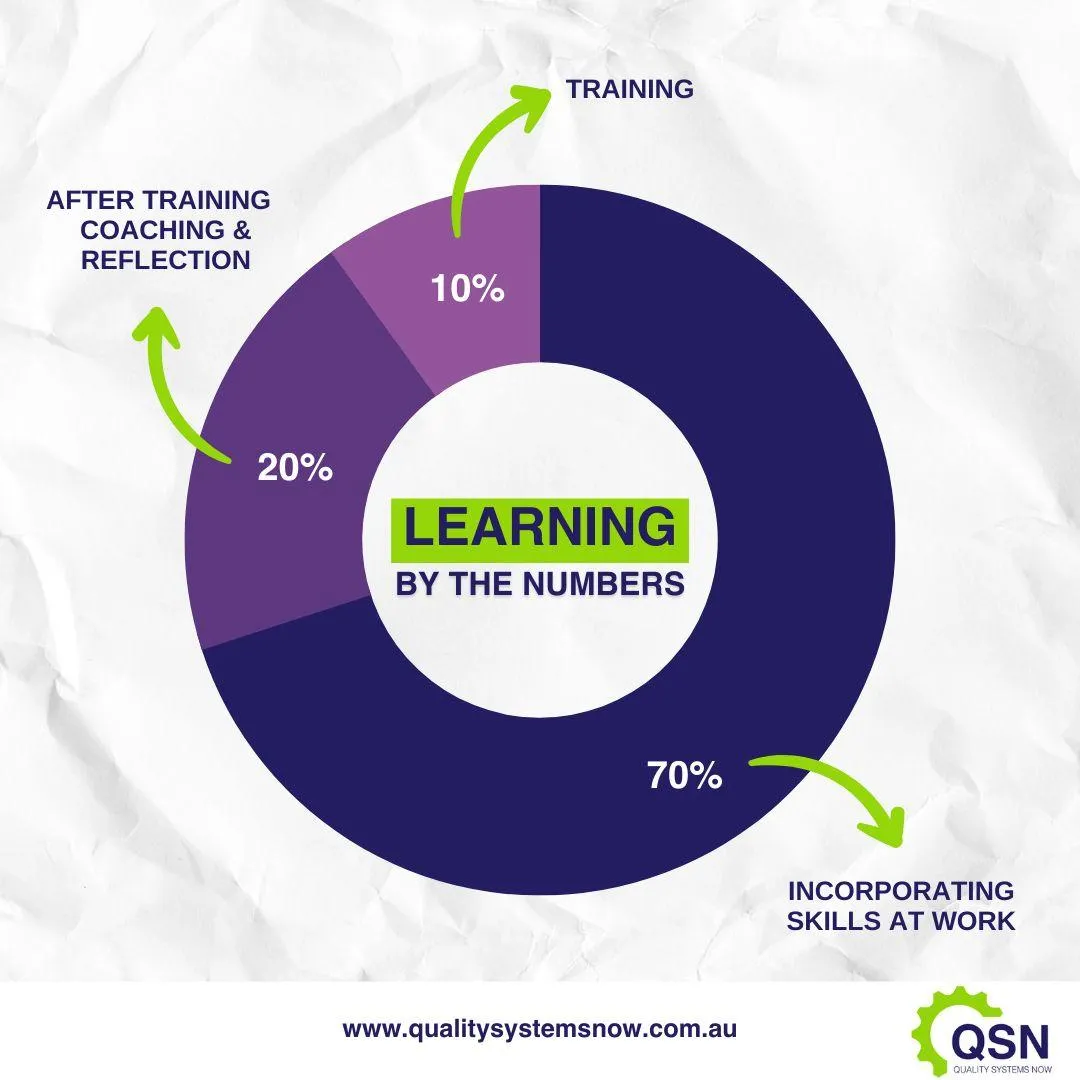

We all know that people learn and retain knowledge the most when they practice what they are learning.

So, when a company only trains it's people by getting them to read procedures, why is that expected to be successful?

The output of the training program should be competent trainees. Yes, reading procedures is part of it, but practice applying what's in the procedure is the whole point. Learning and training might be different things - for many companies, their training program is a tick in the box to say that someone has read a document at least once. They may or may not have understood it.

They may have no idea how to do it in practice. In a quality culture organisation, training and learning are integrated with doing and improving. It's not an easy one to do in practice, that's why so many companies have a 'tick in the box' and 'ready the SOP' mentality.

A thorough training rpogram, with competency based learning, especially for tasks on the shop floor, requires resources and rigor. So it's often the first system to be cannabilised when resource is tight and rigor is loose. What does your company do to make sure staff are competent in their activities? Is it a quality culture approach or could it be improved?

And for those interested in joining me in a deep dive into all things quality culture, check out my mastermind group - the link is in the comments. #qualityculture #pharmaceuticals #medicaldevice #gmp #biotech